Recovery and Utilization of Autoclave Waste Heat by Autoclave Lime Sand Brick Making Machine

Autoclaving isAutoclaved Lime Sand Brick Making MachineIt is an indispensable link in the production and also a key link affecting the quality of autoclaved bricks. Autoclaving in an autoclave greatly increases the strength of the brick embryo. However, relevant data show that my country is one of the countries with serious waste of resources in the world, ranking 56th among 59 countries surveyed. Coupled with the fact that energy saving has become the consensus of the society, the recovery and utilization of waste heat in autoclaves is of great significance for energy saving. the

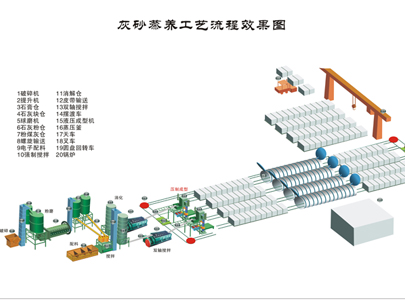

The production energy consumption of my country's building materials industry accounts for about 90% of the total energy consumption in the country, accounting for 13% of industrial energy consumption, sulfur dioxide emissions account for 14%, and dust and smoke emissions account for 55% of national industrial emissions. Materials account for 23% of the total energy consumption of the building materials industry. At present, in silicate building materials (autoclaved bricks are made of calcareous and siliceous materials) product factories, the common curing process-autoclaved curing uses high-temperature, high-pressure saturated water vapor as the heat medium, and steams in the pressure volume. Realized in the autoclave.Autoclaved Lime Sand Brick Making MachineWhen making bricks, in the autoclave, when high-temperature saturated steam is fed in, heat exchange is performed between the steam and the green body, between the steam and the kettle body and steam curing vehicles, and the unit heat consumption of saturated steam is generally 220kg /m3-300kg/m3, when the production management is good and the waste heat is utilized, it may be lower than the above range. Relevant data display: inAutoclaved Lime Sand Brick Making MachineDuring the brick-making process, during the entire autoclave curing, the heat consumed by heating products accounts for about 35%-37%, the heat of heating equipment accounts for about 20%-23%, and the loss of heat loss accounts for about 3%. The heat content of steam in the inner free space is about 5%-6.5%, and the heat content of condensed water is about 30%-33%. When the heat preservation of the attached body is good and the autoclave is used continuously, the utilization rate of heat will be higher.

However, from the perspective of energy saving,Autoclaved Lime Sand Brick Making MachineThe heat of heating products and heating equipment is unavoidable when making bricks, and heat loss always occurs, but it can be reduced to a lower level by good insulation, and the residual gas and condensed water of the autoclave can be reused . This part of waste heat accounts for 33%-38% of the total heat consumption. If it is used well, it can reduce energy consumption and save energy.

Prev: What should a cost-effective hydraulic brick machine have?

Next: Cost-saving method of hydraulic unburned brick machine